Advanced Industrial Machine Monitoring with IoT and AI: A Predictive Maintenance Revolution

Discover how smart machine monitoring using IoT, AI, and Edge Computing transforms industrial efficiency through real-time tracking of vibration, temperature, and current.

Introduction: The Future of Machine Health Monitoring

In today’s fast-evolving industrial landscape, real-time machine monitoring has become essential. Companies across sectors are adopting IoT (Internet of Things), AI (Artificial Intelligence), and Edge Computing to track vital machine parameters like vibration, temperature, and current—ensuring optimal performance, minimizing downtime, and reducing maintenance costs.

At Huebits, we offer an intelligent machine monitoring solution that collects, processes, and analyzes data in real-time, helping manufacturers embrace Industry 4.0 practices with confidence.

Why Vibration, Temperature, and Current Monitoring Matters

Vibration: Early indicator of imbalance, misalignment, or wear in rotating machines.

Temperature: High temperatures often precede equipment failure due to friction or overheating.

Current: Sudden increases or drops in current signal electrical faults, load imbalances, or inefficiencies.

Combining these parameters creates a holistic view of machine health, enabling predictive maintenance instead of reactive repairs.

Huebits Smart Machine Monitoring Solution

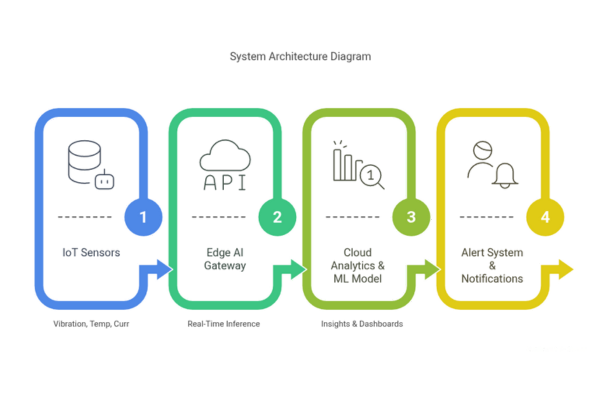

1. IoT Sensors and Data Acquisition

Vibration sensors (accelerometers)

Temperature sensors (thermistors, RTDs)

Current transducers and CT coils

These sensors are deployed on critical machines to collect continuous telemetry data.

2. Edge AI Processing

Collected data is processed on-site using edge computing nodes (e.g., Raspberry Pi, NVIDIA Jetson).

AI models trained to detect anomalies in vibration, temperature, and current trends.

Alerts generated in real-time—no cloud latency.

3. Cloud-Based Insights and Dashboarding

Long-term trend analysis

Custom rule-based or ML-based threshold detection

Intuitive dashboards for maintenance teams

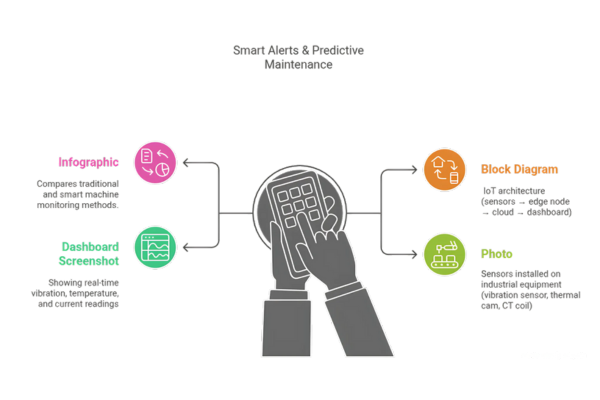

4. Smart Alerts & Predictive Maintenance

Notifications via SMS, email, or app when critical thresholds are exceeded.

Predict component wear, bearing failure, or overheating events days in advance.

Technology Stack

Hardware: ESP32, Raspberry Pi, Jetson Nano, Arduino, industrial-grade sensor kits

Sensors: ADXL345, LM35, MAX6675, CT coils (SCT-013), thermal imaging sensors

Protocols: MQTT, HTTP, Modbus, OPC-UA

Edge AI Frameworks: Edge Impulse, TensorFlow Lite, OpenCV

Cloud Platforms: AWS, Azure IoT, Google Cloud, HueBits Cloud

Data Visualization: Grafana, HueBits Custom Dashboards

Benefits of IoT-Powered Machine Monitoring

🔍 Proactive Failure Detection: Reduce unplanned downtime by up to 60%.

🛠️ Cost Savings: Slash maintenance costs by avoiding catastrophic failures.

🕒 Efficiency Boost: Real-time data helps optimize maintenance scheduling.

⚡ Energy Monitoring: Track energy consumption trends for optimization.

📊 Improved Asset Life: Continuous monitoring leads to longer equipment lifespan.

Real-World Applications

1. Manufacturing Plants: Monitor CNC machines, compressors, and motors.

2. Energy Sector: Real-time monitoring of generators, turbines, and transformers.

3. HVAC Systems: Detect motor wear, airflow issues, and compressor failures.

4. Water Utilities: Monitor pumps and motors for overload and vibration anomalies.

5. Smart Buildings: Track motor-driven systems in lifts, escalators, and HVAC units.

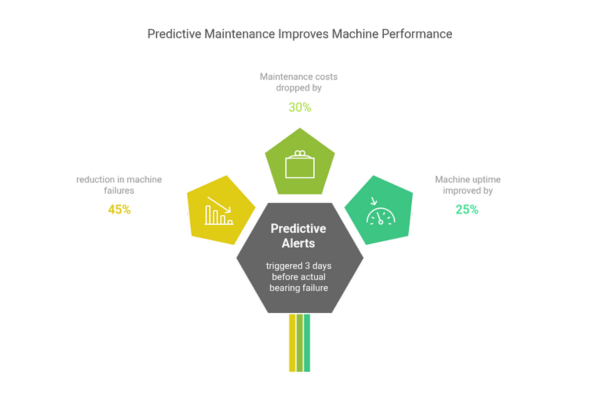

Case Study: Predictive Maintenance for a Motor Assembly Line

A mid-sized automotive component manufacturer deployed Huebits’ machine monitoring on 12 motor stations. Over 6 months:

System Architecture Diagram

Why Choose Huebits?

🧠 AI-Driven Predictive Algorithms

⚙️ Seamless Integration with Legacy Systems

📱 Cross-platform Dashboards & Alerts

🧩 Modular, Scalable Architecture

🌍 Industry-agnostic deployment: Manufacturing, Energy, Utilities, and More

Transform Your Factory Floor with Real-Time Machine Intelligence

Huebits empowers manufacturers with smart machine monitoring solutions that detect faults before they happen—using IoT, Edge AI, and real-time analytics to minimize downtime and maximize efficiency.

Ready to modernize your maintenance strategy?

Let’s bring predictive insights to your machines today.