Achieving Peak Operational Efficiency: Streamlining Business Operations with Databricks

Discover how leading manufacturers use scalable machine learning, demand forecasting, and data lakehouse architecture to drive operational efficiency and improve supply chain management.

Introduction: The Need for Efficiency in Modern Manufacturing

As the manufacturing sector grows more competitive, companies are increasingly turning to data-driven strategies to enhance efficiency, improve decision-making, and stay ahead of industry trends. With massive amounts of data generated daily, traditional data platforms are no longer sufficient to provide the agility and insights required for businesses to remain competitive. Manufacturers must adopt scalable, flexible, and integrated systems that allow them to harness the power of their data in real-time.

The integration of cutting-edge tools such as Databricks on Azure has enabled manufacturers to break down data silos, unlock actionable insights, and democratize data across the organization. This transformation not only optimizes operational processes but also drives better forecasting, smarter supply chain management, and continuous improvement in product availability.

Challenges: Overcoming Legacy Systems and Data Silos

Manufacturers today face the dual challenge of managing a complex and fragmented data ecosystem while trying to derive actionable insights from diverse sources. Legacy on-premises systems often create data silos that prevent departments from collaborating effectively and accessing real-time information.

For many companies, this centralized, rigid data infrastructure makes it difficult to scale operations and adapt to changing market demands. To stay ahead, manufacturers need an open, scalable, and flexible data platform that allows different teams—from business analysts to data scientists—to collaborate, innovate, and solve operational challenges independently.

The need for a next-generation data architecture that supports predictive analytics, real-time monitoring, and self-service data capabilities is now more critical than ever.

Solution: Unlocking Data Potential with Lakehouse Architecture

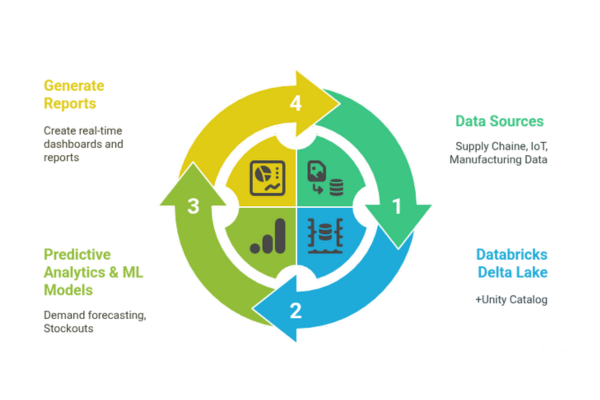

To address these challenges, manufacturers are turning to Databricks and Azure, combining their capabilities into a unified data architecture that supports large-scale data processing, predictive analytics, and machine learning at scale. The adoption of a Lakehouse Architecture allows manufacturers to bridge the gap between traditional data lakes and data warehouses, providing an integrated platform for both transactional and analytical workloads.

Key Benefits of the Solution:

Real-Time Data Processing: With Databricks and Delta Lake, manufacturers can ingest, process, and analyze data from multiple sources in real time, making it easier to predict demand fluctuations and respond proactively.

Machine Learning for Predictive Insights: By leveraging machine learning algorithms, manufacturers can forecast demand, optimize inventory levels, and prevent supply chain disruptions before they occur.

Data Democratization: Databricks allows users across the organization to access secure and trusted data, enabling teams to build their own data products and leverage advanced analytics without relying heavily on IT resources.

Improved Governance: With robust data governance frameworks, manufacturers can ensure that data is secure, compliant, and accessible only to authorized users, empowering teams to act based on the most up-to-date information.

Tech Stack Overview:

Cloud Platform: Azure

Data Platform: Databricks Lakehouse (Delta Lake, Unity Catalog)

Languages: Python, SQL, Scala

ML/AI: Databricks ML, TensorFlow, scikit-learn

Data Ingestion: Kafka, MQTT, Azure Event Hub

Storage: Azure Data Lake, Delta Lake

Visualization: Power BI, Tableau

Governance: Unity Catalog, Role-based Access Control

Architecture: Scalable and Integrated Data Ecosystem

Key Use Cases and Business Impact

1. Demand Forecasting

Machine learning models trained on historical production, sales, and supply chain data can accurately predict future demand, enabling manufacturers to optimize production schedules and align resources accordingly. The result:

📈 Improved production planning with up to 25% better accuracy

📉 Reduction in excess inventory by 18%

2. Supply Chain Optimization

Real-time data and predictive insights allow manufacturers to optimize their supply chain, reduce delays, and ensure on-time deliveries. This leads to:

🚚 15% reduction in supply chain delays

🏭 Improved operational efficiency with a 12% faster inventory turnover

3. Safety Stock Management

Using predictive analytics, manufacturers can optimize their safety stock levels to prevent stockouts while minimizing overstocking. Benefits include:

📦 18% reduction in safety stock and associated costs

🔄 Better resource allocation, minimizing waste

4. Manufacturing Performance Monitoring

The ability to monitor plant performance in real-time ensures faster identification of production bottlenecks and machine maintenance needs, resulting in:

⚙️ 20% increase in machine uptime

🔧 30% improvement in production line efficiency

Results: Transforming Operations and Redefining Efficiency

By adopting Databricks and Azure, manufacturers have seen dramatic improvements in their operational capabilities. Key outcomes include:

👥 Platform adoption grew by 60% within the first year

💼 Enhanced decision-making speed with a 25% reduction in time-to-insight

💰 Cost savings from better demand forecasting, reducing operational waste by 20%

📦 Improved product availability leading to higher customer satisfaction and loyalty

Conclusion: Driving the Future of Manufacturing with Data

The shift toward a data-driven operational model is no longer optional—it's essential for manufacturers seeking to stay competitive in today’s fast-paced market. By leveraging the power of Databricks and Azure, manufacturers can unlock the true potential of their data, optimize operations, and drive intelligent, real-time decision-making.

With the Lakehouse Architecture, manufacturers can seamlessly integrate their operational and analytical data, scale machine learning models, and enable collaboration across departments. This transformation not only optimizes current operations but also prepares manufacturers for future growth and innovation.

As the industry continues to evolve, the companies that embrace data-driven strategies will be best positioned to lead the way toward smarter, more sustainable manufacturing.

📩 Contact us today to learn how our data-driven solutions can help streamline your manufacturing operations and drive peak efficiency.

Ready to Power Up Your Manufacturing Operations?

Huebits helps manufacturers unlock the full potential of their data using Databricks, Azure, and scalable machine learning solutions. Whether it’s improving forecasting accuracy, boosting production efficiency, or reducing supply chain delays — we’ve got the tools to get you there.

Want to build a modern, AI-ready data architecture for your operations?

Let’s design your path to peak efficiency