Revolutionizing Industrial Intelligence: A Full-Scale Case Study in Machine Learning, IoT, and Edge AI by Huebits

Discover how Huebits is paving the way for intelligent industries with a robust integration of IoT, Edge AI, and machine learning—enabling real-time analytics, predictive maintenance, and autonomous control at scale.

Introduction: Welcome to the Intelligent Industrial Era

The Fourth Industrial Revolution is here—and data is the new oil. Yet raw data alone is not enough. What matters is intelligence at the source.

Huebits empowers industrial enterprises to evolve into intelligent, self-optimizing ecosystems using IoT, Edge AI, and Machine Learning. Our solutions enable machines to think, predict, and adapt autonomously—enhancing productivity, reliability, and competitiveness.

Edge AI and IoT together make up the cornerstone of cyber-physical systems, where devices at the edge of the network perform real-time data analysis and decision-making, often without the need for cloud dependency. This results in reduced latency, improved privacy, and seamless operations, especially in mission-critical environments.

Case Study: Smarter Maintenance and Monitoring Across Three Plants

Client Profile: A multi-location industrial manufacturing company with heavy-duty rotating machinery, facing increasing unplanned downtimes and high maintenance overheads.

Challenge: Manual maintenance cycles and legacy SCADA systems couldn't predict failures or optimize energy use across the three geographically separated plants.

Vision: Partner with Huebits to build a real-time intelligent monitoring system powered by IoT, Edge AI, and machine learning.

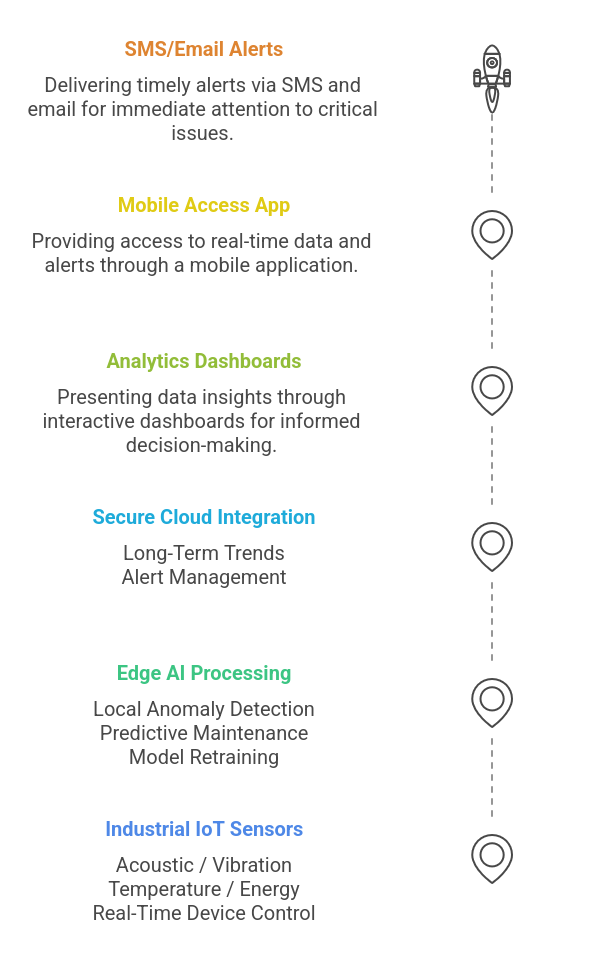

Our Solution: Edge-First Machine Intelligence Framework

1. IoT Sensor Grid Deployment

Sensors attached to motors, gearboxes, and HVAC systems for:

Vibration (accelerometers)

Temperature & humidity

Acoustic patterns (I2S microphones)

Power consumption (smart energy meters)

2. Edge AI Gateways

Localized ML inferencing using ESP32-S3 and NVIDIA Jetson Nano.

Real-time evaluation of spectral vibration data using FFT + anomaly detection.

Local storage fallback and OTA (Over-the-Air) model updates.

3. Machine Learning Engine

Historical equipment performance data used to train:

Regression models for lifespan prediction

Classification models for fault detection

Clustering models for anomaly detection

4. Cloud Integration + Action Layer

Real-time data pushed to secure cloud via MQTT/HTTPS.

Visual dashboards and KPI analytics updated every 5 seconds.

Automated alerts triggered for maintenance, overheating, or vibration thresholds.

Actions: Automatic load balancing, cooling activation, or equipment shutdown.

Solution Architecture Diagram

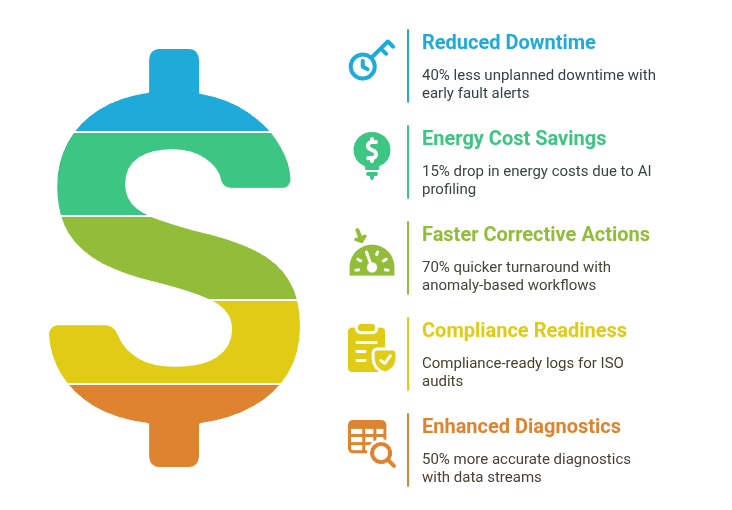

Predicted Impact Within 6 Months

🛠 40% less unplanned downtime with early fault alerts via Edge AI

🔌 15% drop in energy costs due to AI-based consumption profiling

🔁 70% quicker turnaround for corrective actions with anomaly-based workflows

📏 Compliance-ready logs and evidence for ISO 50001, 27001 audits

🔍 50% more accurate diagnostics by combining audio, power, and vibration data streams

Innovation Highlights: What Makes Huebits Different

Innovation Area Technical Feature Business Benefit

Edge AI

Inference Models run directly on edge gateways (ESP32/Nano) No latency, works offline

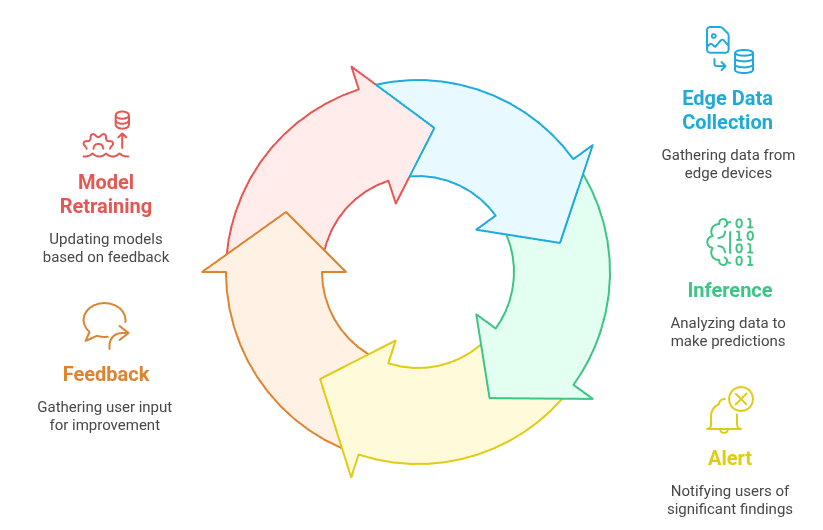

Feedback Loop

ML Human-in-the-loop feedback for anomaly labeling Model accuracy increases over time

Multimodal

Sensing Vibration + Sound + Current = precise diagnostics Reduced false positives

Auto-Scaling

Cloud Dynamic compute allocation based on real-time demand Efficient cloud cost usage

OTA Model

Updates Push latest ML models to all edge nodes securely Future-proof and scalable deployment

Suggested Diagram: Continuous loop of Edge Data → Inference → Alert → Feedback → Model Retraining.

Theory Behind the Tech

Machine Learning on the Edge allows predictive algorithms to run near the data source. This minimizes latency and enables instant decision-making—ideal for time-sensitive applications like equipment failure prevention.

Edge AI combines edge computing with embedded artificial intelligence. It enables real-time data processing without relying heavily on centralized servers, improving data privacy and lowering bandwidth usage.

IoT (Internet of Things) acts as the nervous system of the industrial setup. It collects granular data through sensors and devices, enabling rich datasets for analytics and model training.

Together, these technologies create a self-adaptive environment where insights are generated close to where events occur, drastically reducing decision latency.

Industry Applications

Huebits’ smart intelligence systems are tailored to deliver value across sectors:

🏭 Manufacturing: Real-time plant efficiency and downtime prediction

🔌 Energy Sector: Load balancing, fault isolation, transformer monitoring

🥫 Food & Beverage: Cold chain compliance, motor-driven processing checks

🏗️ Construction: Structural vibration monitoring, safety compliance tracking

🚛 Logistics: Asset tracking, fleet condition monitoring, route optimization

🧬 Pharmaceuticals: Environmental monitoring, smart cleanrooms, predictive equipment calibration

Built to Scale, Secure, and Comply

🔒 Zero Trust Security Architecture

☁️ Cloud-Edge Hybrid Setup

⚙️ Supports Major Industrial Protocols (Modbus, OPC UA, MQTT)

📊 Industry-Specific KPI Dashboards

🌍 Cross-Plant Deployment with Centralized Visibility

Final Takeaway: Intelligence at the Source is the Future

The industrial world is evolving. Real-time intelligence isn’t just an upgrade—it’s the new foundation.

📩 Partner with Huebits to bring machine intelligence into your plant, reduce waste, prevent failures, and maximize operational excellence.

Build Smarter, Predictive Industrial Systems with Huebits

Transform your plants into intelligent, self-optimizing ecosystems powered by IoT, Edge AI, and Machine Learning.

Reduce downtime, boost efficiency, and future-proof your operations.